JAMES WATT 1736 - 1819 (G2, G3a,

G3b, G3c)

xxxxxThe Scottish engineer James

Watt was trained as a mathematical instrument maker, and also spent

some years as a canal surveyor. In 1775, however, he went into

partnership with Matthew Boulton, a local industrialist, and began

work on improving the pumping machine invented by the English

engineer Thomas Newcomen in 1712

(AN). He quickly improved its economy and

efficiency by isolating the condenser and insulating the cylinder.

It was not until the early 1780s, however, that he made two

revolutionary improvements. By 1782 he had made the engine "double-acting" (whereby

the piston pushed as well as pulled) and, by means of special

gearing, he had converted this movement into the rotary movement of

a wheel. This meant that steam power was now readily available as a

driving force for a whole variety of industries. No longer dependent

upon water power, they could now establish factories near to two

vital needs - coal and a ready labour force. The factory system

was about to put the Industrial Revolution into its second and very

active phase.

xxxxxAs we have seen, it was in 1712

(AN) that the English engineer Thomas

Newcomen produced his steam engine. Although somewhat crude and

unreliable, it was eventually used to pump water out of mines across

the country, especially in Cornwall. Several years later the

Yorkshireman John Smeaton almost doubled the efficiency of the

engine, and by 1755 it was being exported to North America. It was

left to the Scottish engineer James Watt, however, by a series of

inventions, to turn Newcomen's engine into a highly efficient,

industrial machine, and start the Age of Steam.

xxxxxAs we have seen, it was in 1712

(AN) that the English engineer Thomas

Newcomen produced his steam engine. Although somewhat crude and

unreliable, it was eventually used to pump water out of mines across

the country, especially in Cornwall. Several years later the

Yorkshireman John Smeaton almost doubled the efficiency of the

engine, and by 1755 it was being exported to North America. It was

left to the Scottish engineer James Watt, however, by a series of

inventions, to turn Newcomen's engine into a highly efficient,

industrial machine, and start the Age of Steam.

xxxxxWatt

was born at Greenock, where his father, a local magistrate, had

quite a thriving business building houses and ships. He was trained

as a mathematical instrument maker from the age of 17, and in 1757,

at the age of 21, he opened a small workshop in Glasgow University.

It was during this period that he was asked to repair a Newcomen

engine, and he conjured up some ideas on how it might be improved.

In 1766, however, he took up work

as a canal surveyor, and for the next eight years spent much of his

time in Scotland. Nevertheless in 1769 he took out a patent for "A

New Invented Method of Lessening the Consumption of Steam and Fuel

in Fire Engines."

xxxxxItXwas not really until 1775 that, having settled in

Birmingham, he turned a practical hand to manufacturing engines. In

that year he went into partnership with Matthew

Boulton (1728-1809) a local

industrialist of proven technical ability who was anxious to adapt

steam power for factory production. Watt worked at Boulton's Soho

Foundry near Birmingham, and soon made some radical and highly

beneficial changes to Newcomen's basic design. For a start, he

greatly increased economy by incorporating a separate, water-cooled

condenser, thus avoiding the serious loss of steam that occurred

with the constant heating and cooling of the cylinder. And he also

substantially improved efficiency by insulating the cylinder itself,

thereby keeping it at steam temperature.

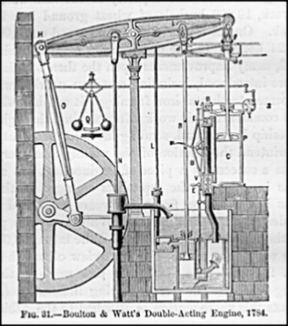

xxxxxFor

the next five years or so Watt was busy installing his much improved

version of the Newcomen model in tin and copper mines in Cornwall.

During this time, however, he continued his refinement of the

engine, and by 1782 had come up with two

highly significant improvements. Firstly, by admitting steam to both

ends of the cylinder so that the piston was pushed as well as

pulled, he had produced a "double acting engine", as in modern

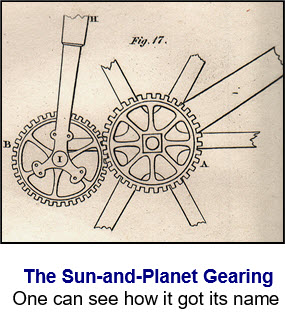

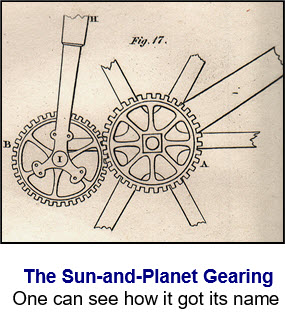

machines. Secondly, by means of mechanical attachments -

collectively known as "sun-and-planet gearing" - he

had converted this back and forth action into the rotary movement of

a wheel. The effect of this innovation on industry would be

difficult to  exaggerate.

In the short-term, it replaced waterpower with steam power in

the cotton and woollen mills operating in the north. In the long

term, it meant that a wide variety of factories - such as flour

mills, paper mills, iron mills and distilleries - could now be

mechanised and built near to coal mines for the source of their

power, and close to large towns for the source of their labour

force. Indeed, in 1782 the master potter Josiah

Wedgwood became the first manufacturer to install a steam-powered

engine in his plant at Etruria. The factory system had arrived, and

destined to grow at an alarming rate. Furthermore, this rotative

engine could be employed in canals, waterworks and the like. The

Industrial Revolution was

about to move into its second phase. It is estimated that by the

turn of the century Watt and Boulton had built some 300 of these

engines.

exaggerate.

In the short-term, it replaced waterpower with steam power in

the cotton and woollen mills operating in the north. In the long

term, it meant that a wide variety of factories - such as flour

mills, paper mills, iron mills and distilleries - could now be

mechanised and built near to coal mines for the source of their

power, and close to large towns for the source of their labour

force. Indeed, in 1782 the master potter Josiah

Wedgwood became the first manufacturer to install a steam-powered

engine in his plant at Etruria. The factory system had arrived, and

destined to grow at an alarming rate. Furthermore, this rotative

engine could be employed in canals, waterworks and the like. The

Industrial Revolution was

about to move into its second phase. It is estimated that by the

turn of the century Watt and Boulton had built some 300 of these

engines.

xxxxxNotxsurprisingly, by 1790 Watt was a wealthy man, and

honoured for his achievements. Hexand

Boulton were elected fellows of the Royal Society in 1785, and both

were prominent members of the Birmingham

Lunar Society, so named because it met

monthly at the full moon. This highly influential organisation was

formed in 1766 to promote science and industry, and included among

its members the chemist Joseph Priestly, the pottery manufacturer

Josiah Wedgwood, and the physician and poet Erasmus Darwin. Watt

went into semi-retirement in 1790, but in 1802, following the

signing of the Peace of Amiens, he and his wife travelled in France

and Germany.

xxxxxIncidentally, it was Watt who first used the term "horse power" as a

measure of power. He employed it to compare the power of the steam

engine with that of a horse, though, in fact, he exaggerated the

pulling power of the horse by some 50 percent. The unit of

electrical power - which is linked to horsepower - was

named after him.

Acknowledgements

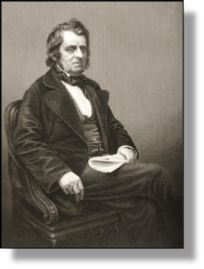

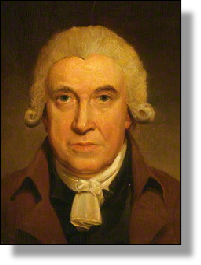

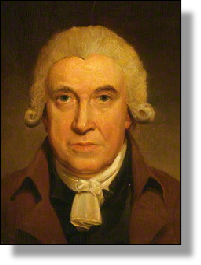

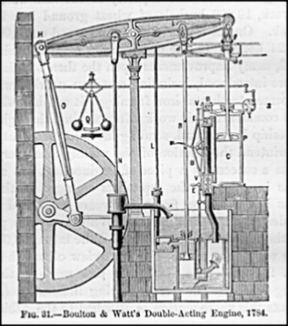

Watt: oil on wooden panel, by

the English painter Henry Howard (1769-1847), c1797 – National

Portrait Gallery, London. Engine: diagram

contained in The Development of the Modern Steam

Engine by James Watt and his Contemporaries by the American

engineer Robert H. Thurston (1839-1903). Gearing:

diagram contained in The Steam Engine Familiarly

Explained and Illustrated by the Irish scientific writer

Dionysius Lardner (1793-1859), published 1852. Wilkinson: by the English portrait painter Lemuel Francis Abbott

(c1760-1802) – Wrexham County Borough Museum and Archives,

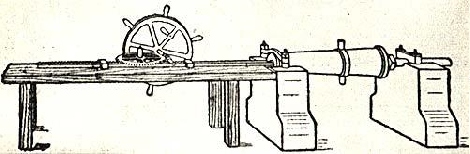

North Wales, UK. Cannon: artist unknown,

diagram contained in A Popular History of

American Invention by the

American science writer Waldemar Kaempffert (1877-1956),

published in 1924. Roebuck: engraving by

Daniel J. Pound (active 1842-1877) after a photograph by John

Jabez Edwin Paisley Mayall, contained in The

Drawing-Room Portrait Gallery of Eminent Personages,

published in The Illustrated News of the World,

London, 1860 – private collection.

G3a-1760-1783-G3a-1760-1783-G3a-1760-1783-G3a-1760-1783-G3a-1760-1783-G3a

Including:

John

Wilkinson

xxxxxThe English ironmaster John Wilkinson (1728-1808)

played an essential part in the making of Watt's ultimate engine. In

1774 he had produced a highly efficient machine for boring the

barrels of cannons. This was adapted to assist Watt in the making of

his much improved cylinder. As Watt's design for this vital part

required a high degree of precision work it could not have been

produced, in fact, without Wilkinson's extraordinary piece of tool

machinery. As we shall see, machine tools of this kind of quality

were later to be developed by such British precision engineers as

Henry Maudslay, James Nasmyth and Joseph Whitworth. Wilkinson also designed a furnace with

enabled pig iron to be re-melted - thus enabling foundries

to be built away from production sites - and it was at his

works at Broseley, Shropshire, that he produced castings for the

iron bridge built by Abraham Darby in 1779, and pipework and fittings for the Paris waterworks. He

was also the first engineer to make an iron-hulled barge,

considered necessary to transport the heavy military equipment he

was making for the government.

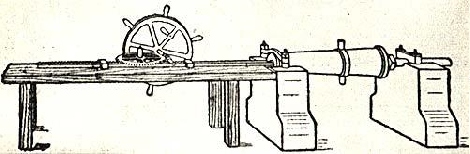

xxxxxThe Englishman John Wilkinson (1728-1808), known at large as "the great

Staffordshire ironmaster", played an essential part in the making of

Watt's ultimate engine - a fact not always recognised. In 1774,

working at his father's factory at Bersham, Denbigh, in Wales, he

produced a highly efficient machine for boring the barrels of

cannons (illustrated below). Regarded today as one of the first

examples of a machine tool, this was adapted to assist Watt in the

making of his much improved cylinder. As Watt's design for this

valuable part required a high degree of precision work, it could not

have been produced, in fact, without the use of Wilkinson's

extraordinary piece of tool machinery. Watt's revolutionary engine

of the 1780s, which, via its boost to the factory system,

accelerated the Industrial Revolution, would certainly not have made

its appearance so early in the day had Wilkinson not been around at

the time! As we shall see, machine tools of this kind of quality

were later to be developed by such British precision engineers as

Henry Maudslay, James Nasmyth and Joseph Whitworth.

xxxxxThe Englishman John Wilkinson (1728-1808), known at large as "the great

Staffordshire ironmaster", played an essential part in the making of

Watt's ultimate engine - a fact not always recognised. In 1774,

working at his father's factory at Bersham, Denbigh, in Wales, he

produced a highly efficient machine for boring the barrels of

cannons (illustrated below). Regarded today as one of the first

examples of a machine tool, this was adapted to assist Watt in the

making of his much improved cylinder. As Watt's design for this

valuable part required a high degree of precision work, it could not

have been produced, in fact, without the use of Wilkinson's

extraordinary piece of tool machinery. Watt's revolutionary engine

of the 1780s, which, via its boost to the factory system,

accelerated the Industrial Revolution, would certainly not have made

its appearance so early in the day had Wilkinson not been around at

the time! As we shall see, machine tools of this kind of quality

were later to be developed by such British precision engineers as

Henry Maudslay, James Nasmyth and Joseph Whitworth.

xxxxxHaving

played so vital a role in its production, Wilkinson used the first

steam engine built by Watt to drive a large air pump at his blast

furnace at Broseley, Shropshire. He specially designed this furnace

to re-melt pig iron, an invention which meant that foundries

need not be established close to the production site. And it was

from here that he supplied many of the castings used in the

construction of the first iron bridge, built by Abraham Darby III in

1779. In later

years he made all the pipework and fittings for the Paris

waterworks, and was responsible for the building of a revolutionary

iron-hulled barge, which he used to transport the heavy

military equipment he was making for the government. And,

ironically, he also taught the

French how to bore cannon from solid castings!

xxxxxIncidentally, Wilkinson took his skills as an ironmaster with him to

the grave. He was buried in a cast-iron coffin, made to his own

design! …..

xxxxx……

The portrait of Wilkinson (illustrated

above) was the work of the English painter

Lemuel Francis Abbott, an artist especially remembered for his

portraits of Lord Nelson. ……

xxxxx…… Andxanother ironmaster who

assisted Watt was the inventor John Roebuck

(1718-1794). He was in partnership with the Scottish engineer

for a short time during the 1770s, when he was working on his

improved version of the Newcomen model. Today, however, Roebuck is

mostly remembered for inventing the means of manufacturing sulphuric

acid on an industrial scale - introduced around 1746 - and

for the various improvements he made at his ironworks at Carron in

Stirlingshire, during the 1760s, including the conversion of cast

iron into malleable iron by means of “a hollow pit-coal fire”.

xxxxxAs we have seen, it was in 1712

(AN) that the English engineer Thomas

Newcomen produced his steam engine. Although somewhat crude and

unreliable, it was eventually used to pump water out of mines across

the country, especially in Cornwall. Several years later the

Yorkshireman John Smeaton almost doubled the efficiency of the

engine, and by 1755 it was being exported to North America. It was

left to the Scottish engineer James Watt, however, by a series of

inventions, to turn Newcomen's engine into a highly efficient,

industrial machine, and start the Age of Steam.

xxxxxAs we have seen, it was in 1712

(AN) that the English engineer Thomas

Newcomen produced his steam engine. Although somewhat crude and

unreliable, it was eventually used to pump water out of mines across

the country, especially in Cornwall. Several years later the

Yorkshireman John Smeaton almost doubled the efficiency of the

engine, and by 1755 it was being exported to North America. It was

left to the Scottish engineer James Watt, however, by a series of

inventions, to turn Newcomen's engine into a highly efficient,

industrial machine, and start the Age of Steam.

exaggerate.

In the short-

exaggerate.

In the short-

xxxxxThe Englishman John Wilkinson (1728-

xxxxxThe Englishman John Wilkinson (1728-