xxxxxIn 1709 (AN) the English engineer Abraham Darby replaced charcoal with coke in the smelting of iron and, by so doing, greatly reduced the cost of making wrought iron. In 1784 the Englishman Henry Cort improved the quality of this wrought iron, and reduced the cost further by introducing his “puddling” process, a means whereby the molten iron was stirred or “puddled” to remove impurities, and then passed through grooved rollers in specially designed rolling mills. This made British iron as good as any produced on the continent, and greatly helped in the manufacture of armaments during the Napoleonic Wars. Later came further improvement in production by the Scotsman James Beaumont Neilson in 1828, and then in 1856 (Va) by two inventors working independently, the Englishman Henry Bessemer and the American William Kelly. These advances in production were to give an enormous boost to the Industrial Revolution.

HENRY CORT 1740 -

Acknowledgements

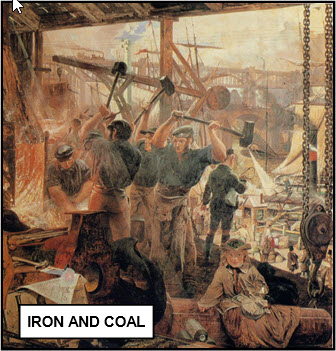

Cort: front cover of book published by The Metals Society, 1983, headquarters Warrendale, Pittsburgh, Pennsylvania, portrait based on print by unknown artist, 1856 – Science and Society Picture Library, Science Museum, London. Ironworks: date and artist unknown. Coal and Iron: by the Scottish artist William Bell Scott (1811-

xxxxxAs we have seen, in 1709 (AN) the English ironmaster Abraham Darby, by a series of experiments, found a means of purifying coal and then using the resulting “coke” to replace charcoal in the smelting of iron. This proved a much cheaper method, and it also made possible the use of larger blast furnaces, thus reducing the cost of production even further. But the making of wrought iron remained a lengthy process, and the quality of the end product left much to be desired. The solution to this had yet to be found.

xxxxxAs we have seen, in 1709 (AN) the English ironmaster Abraham Darby, by a series of experiments, found a means of purifying coal and then using the resulting “coke” to replace charcoal in the smelting of iron. This proved a much cheaper method, and it also made possible the use of larger blast furnaces, thus reducing the cost of production even further. But the making of wrought iron remained a lengthy process, and the quality of the end product left much to be desired. The solution to this had yet to be found.

xxxxxHenry Cort was born in Lancaster, England, and, on leaving school, worked for ten years as a civil agent, purchasing arms for the Royal Navy. At that time -

xxxxxAt first he used the conventional method, producing wrought iron by hammering cast iron in a forge. However, with the sharp rise in the cost of Swedish iron during the American War of Independence, he began making wrought iron from scrap cast iron, and looking for a better means of production. In 1784 he came up with a method whereby iron made molten in a coal- designed rolling mills, revolutionised iron making in Britain. It produced bar iron more quickly, more efficiently and of a much higher quality. It was, declared Cort, as good as the Swedes could offer, and made at a fraction of the cost.

designed rolling mills, revolutionised iron making in Britain. It produced bar iron more quickly, more efficiently and of a much higher quality. It was, declared Cort, as good as the Swedes could offer, and made at a fraction of the cost.

xxxxxHis invention could not have come at a better time for Britain. With the Napoleonic Wars just over the horizon, it meant that the country had no longer to rely on imported iron, having the ready means to produce its own armaments more cheaply and on a larger scale. Over the next 20 years production increased fourfold, whilst the ability to produce wrought iron in various shapes and forms spurred on the Industrial Revolution, paving the way for the introduction of the railways, and the eventual construction of metal ships and buildings.

xxxxxWith the marked increase in the production of iron, it looked as though Cort’s invention was about to bring its reward. But it was not to be. In August 1789 he learnt that his financial backer had invested stolen government funds into the business, and had used the patents governing his inventions as security. With twelve children and another one on the way, Cort was forced into bankruptcy. He was eventually granted a small pension, but he died a poor man.

xxxxxFor a short time puddling furnaces kept up with the demand for wrought iron, but advanced techniques were clearly going to be needed, and they were not long in coming. In 1828 production was further increased by the introduction of the hot-

Including:

The Industrial Revolution

Arthur Young and

Thomas Coke

xxxxxAs we have seen, it was in 1771 (G3a) that the textile “king” Richard Arkwright opened the first factory working by water power, and the Industrial Revolution really took off. This significant development was made possible by a series of inventions in the woollen and cotton industries -

xxxxxAs we have seen, it was in 1771 (G3a) that the textile “king” Richard Arkwright opened the first factory working by water power, and the Industrial Revolution really took off. This significant development was made possible by a series of inventions in the woollen and cotton industries -

xxxxxNot surprisingly, the next thirty years witnessed a number of important inventions in keeping with these fundamental changes. ThexEnglish engineer Joseph Bramah (1748-

xxxxxBut the Industrial Revolution was a long and erratic process. Up to the 1790s the majority of industries were still rural based, and simply provided goods for the home market. As we have seen, it was not until James Watt invented his rotary steam engine in 1782 that industry was given the opportunity of moving away from water power, and factories, based on mass production, began to spring up around coal mines, the new source of power. Such a move was not made overnight, and, in many cases, had to go hand in hand with improved roads and extended canals. The cotton and woollen industries were gen erally the first to make the change, followed by the likes of distilleries, and paper and flour mills.

erally the first to make the change, followed by the likes of distilleries, and paper and flour mills.

xxxxxIn the meantime, (as noted above) more efficient methods of producing wrought iron, such as Cort’s puddling process, gave promise of a new Iron Age. As we shall see, by the time the next break-

xxxxxIncidentally, after Joseph Bramah had invented his “unpickable” lock in 1784, he displayed it in his shop window in 1789, and offered a prize of 200 guineas to anyone who could unlock it. It was 61 years later before an American mechanic, struggling for over 50 hours, met the challenge! We are not told how much prize money he picked up!

xxxxxIncidentally, after Joseph Bramah had invented his “unpickable” lock in 1784, he displayed it in his shop window in 1789, and offered a prize of 200 guineas to anyone who could unlock it. It was 61 years later before an American mechanic, struggling for over 50 hours, met the challenge! We are not told how much prize money he picked up!

xxxxxAs we have seen, the Industrial Revolution began in earnest in 1771 (G3a) when Arkwright opened the first factory worked by water power, made possible by inventions in the woollen and cotton industries, and the development of more efficient engines. Over the next thirty years, Watt invented his rotary engine in 1782, allowing factories to move to coalfields (their new source of power), and there were a number of inventions, including Bramah’s “unpickable” lock and hydraulic press, Maudslay’s metal lathe, Whitney’s cotton gin, and Cartwright’s wool combing machine. And alongside these developments went an improvement in roads, and an extension of the canal system. In addition, Cort’s puddling process gave promise of a new Iron Age, and by the time the next break through came -

xxxxxThe English farmer and writer Arthur Young (1741-

xxxxxThroughout this period, improvements were also taking place in agriculture in an attempt to meet the needs of an increasing urban population. The English farmer and writer Arthur Young (1741-

xxxxxThroughout this period, improvements were also taking place in agriculture in an attempt to meet the needs of an increasing urban population. The English farmer and writer Arthur Young (1741-

xxxxxHe was also responsible for the publication of the Farmers’ Calendar, begun in 1771, and his Annals of Agriculture, first produced in 1784 and running for 45 volumes, provided a valuable vehicle for the exchange of new ideas in farming practices. Among the contributors to this periodical was the king himself, writing under the nom de plume of “Ralph Robinson”. Young’s books on agriculture, containing as they did information on improved methods of crop rotation, the use of different fertilizers, and details of new farming machinery, proved of immense value in their day, both at home and overseas. As we shall see (1815 G3b), work of this nature was continued by the English chemist Humphry Davy. He was one of the first scientists to put his knowledge to good use in the direct service of agriculture.

xxxxxIncidentally, in addition to agriculture, Young also wrote about his travels in France in the late 1780s, and these included some lively and useful accounts of the opening stages of the French Revolution. …… He was a cousin of the novelist and letter writer Fanny Burney.

xxxxxIt was during this time that Thomas Coke (1752 -

xxxxxIt was during this time that Thomas Coke (1752 -

xxxxxIncidentally, as a matter of interest, Coke’s son and heir, Thomas, was the first Englishman to wear a bowler hat. He had one made in 1849 in order to protect his head from overhanging branches when out shooting on his estate. It became a popular form of headdress (sometime known as a coke hat) in the Victorian era, and later became closely associated with the banking fraternity.

G3b-